Integrate tools, devices, and systems across the shop floor into a common platform to error-proof assembly operations.

2,500

700

No more data silos. Only full traceability

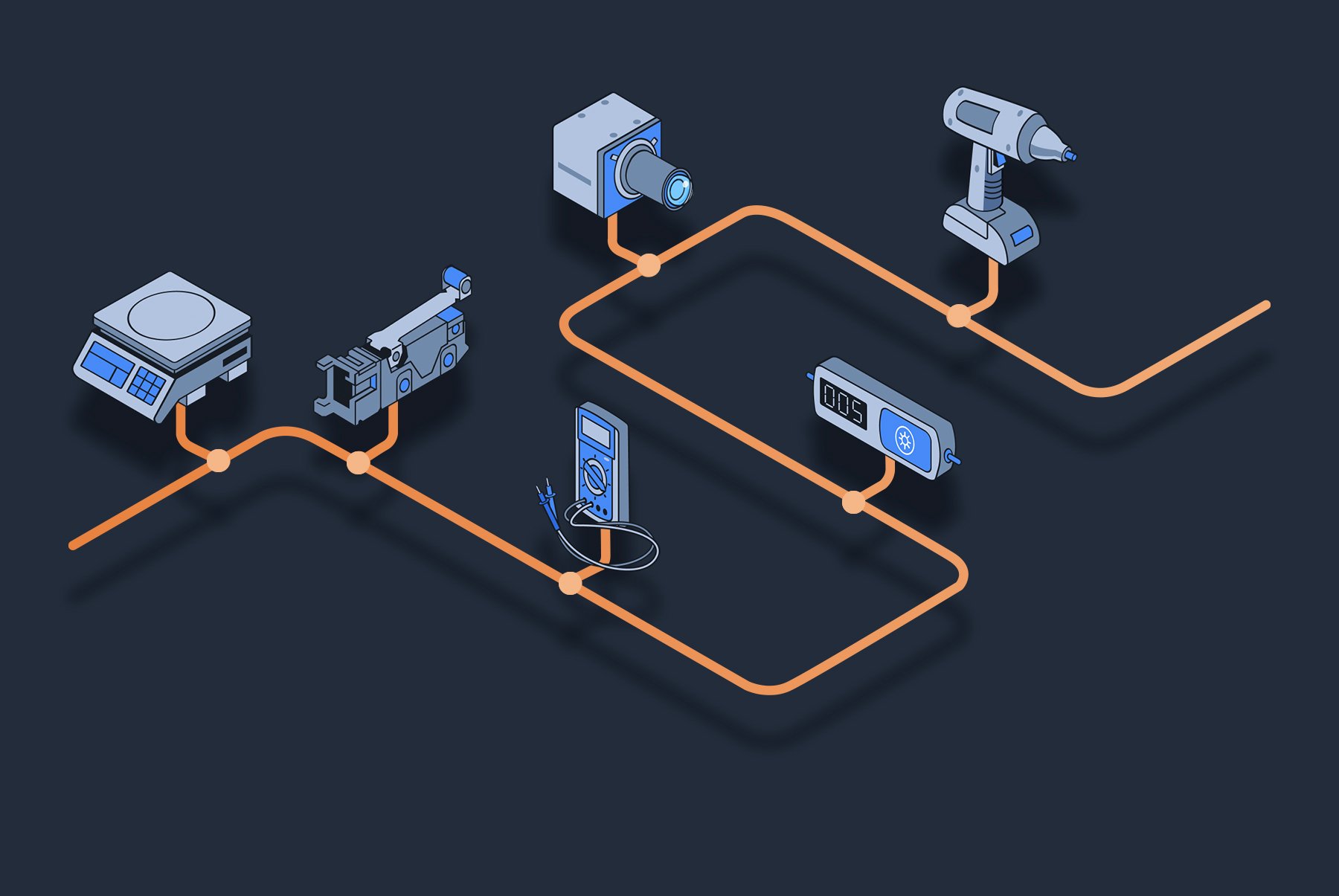

Automate error-proofing for assembly operations

Simplify data collection

In a factory that uses hundreds of different tool brands, it’s easy for data to be isolated. Streamline data collection from common shop floor tools into a single system. Integrate tool performance data with digital work instructions for instant error-proofing

Worker guidance for quality control

Help your operators build products to a common standard of quality. Digital work instructions act as a gatekeeper that aids and doesn’t disturb. Easy to update with rich multimedia content, version control, and process variants.

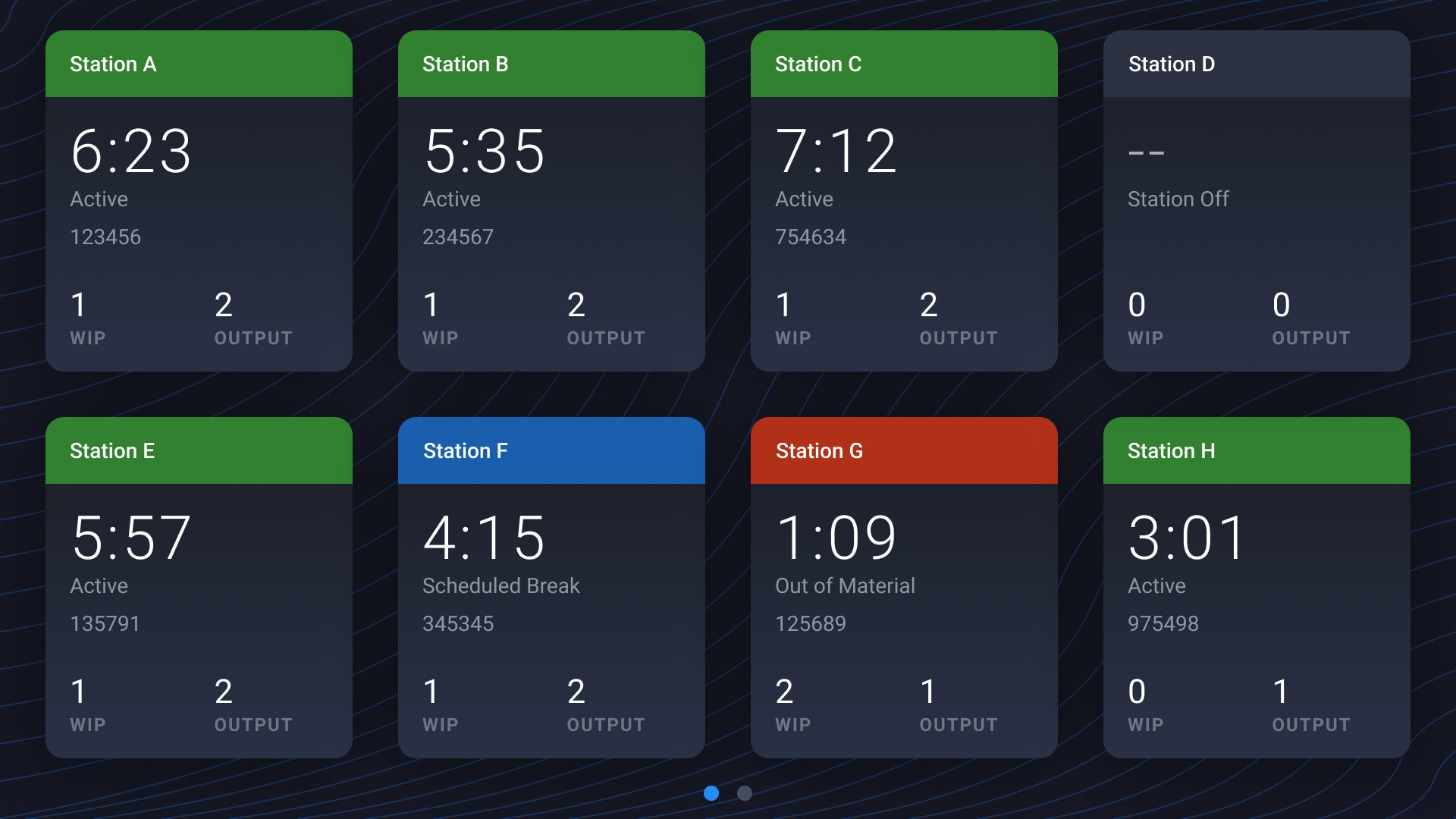

Operational visibility

- "Am I winning or losing today?"

- "Are my operators consistently hitting their production targets?

- "Can I isolate my errors to who built the product and why?"

Arm the operations team with quick insights and give them the bigger picture. Enable them to respond to issues as they happen.

Easy to integrate

Pico MES seamlessly integrates with business systems like ERP, tools, and communication channels. Connecting with existing technology infrastructure is where our customers realize the most ROI.

Empowering manufacturers across America and the world

Here's how we've helped manufacturers feel victorious — enabling their factories to be more efficient, productive, and connected.

Amazing capabilities for a small price

Raakesh B.

Flexibility and Support

Talen G.

Dramatic Production Floor Improvement

Greg W.

Good MES, very helpful

Donald W.

Pico is a must have!

Chris S.

Simple and Easy to use MES

Trevor O.

PICO MES

Jarrett H.

Heavy Duty Truck Manufacturer

Cody C.

Gain access to hundreds of solutions from a single platform

Step into the future of factory operations with Pico MES. Start your journey toward a more efficient, error-proof factory floor today.