Shop floor software that instantly turns your factory into a smart factory with your existing people and tools

Not another system that’s going to take millions of dollars to install over 2 years

Not another 'project' that over-burdens your team. PICO is designed exclusively for the shop floor with effortless integration and instant ROI. Let's build high-quality products with no drama.

-1.png)

Why should you implement digital work instructions & operator guidance?

It's simple–shop floor software eliminates guesswork for your frontline operators. Digital work instructions are easy to create and edit with version control. Supplement with colorful multimedia content as visual aids. The digital operator guidance empowers employees to build complex products without mistakes and errors, improving product quality and operator confidence.

Shop floor software that connects with 330+ IOT tools, devices, and systems

No-code integration from hundreds of common shop floor tools, ranging from torque tools, barcode scanners, AI cameras, and leak testers enables engineers to drag and drop these tools into their workflow. Rapidly deploy and automate data capture from hundreds of options.

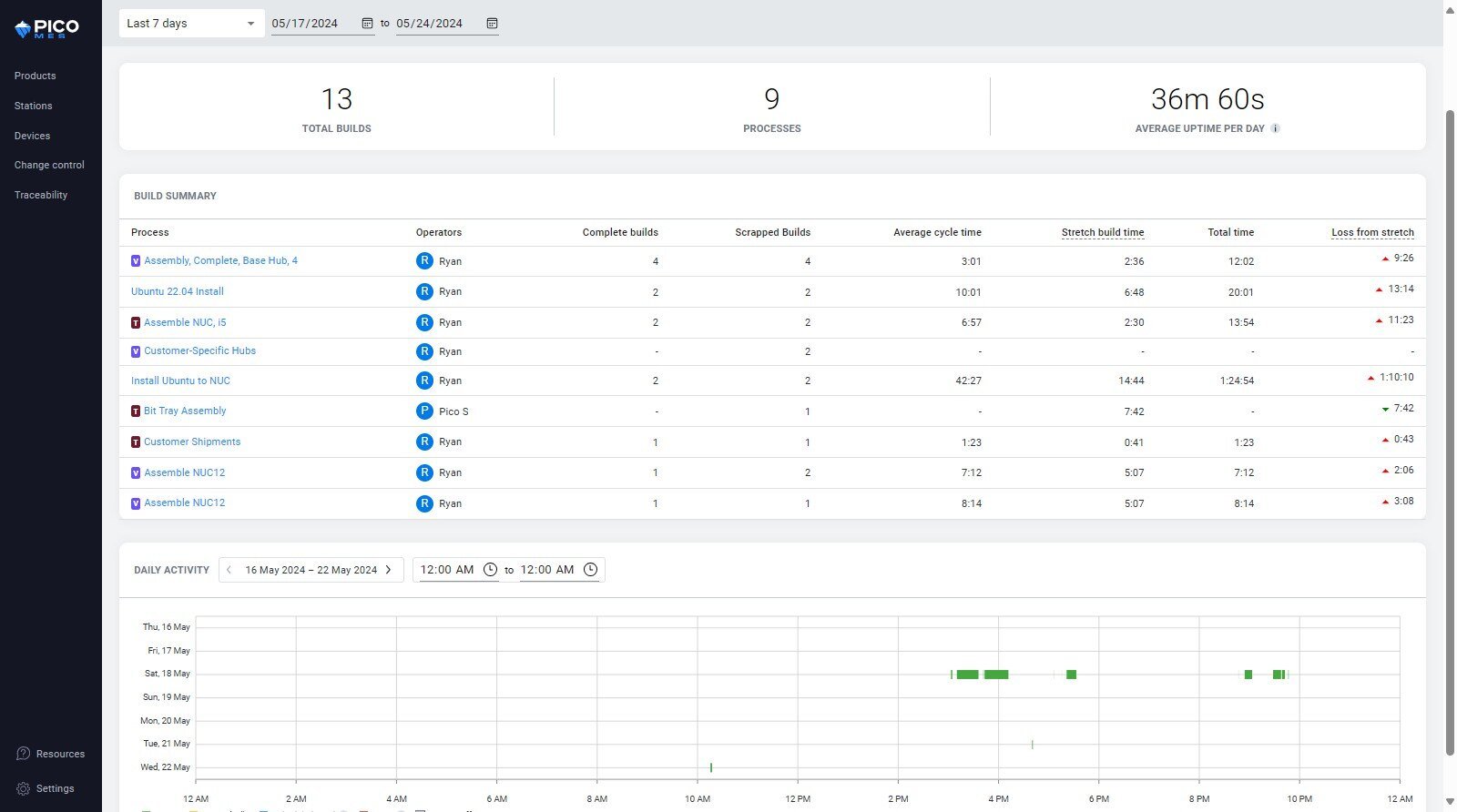

Shop floor analytics: Data for continuous improvement in discrete manufacturing

Ditch the stopwatch and clipboard. Harness real-time data for continuous improvement in cycle time and operator efficiency. Pull data into your favorite BI tools such as Power BI, Tableau, HEX, MS Excel, and Sigma to streamline analytics and reporting.

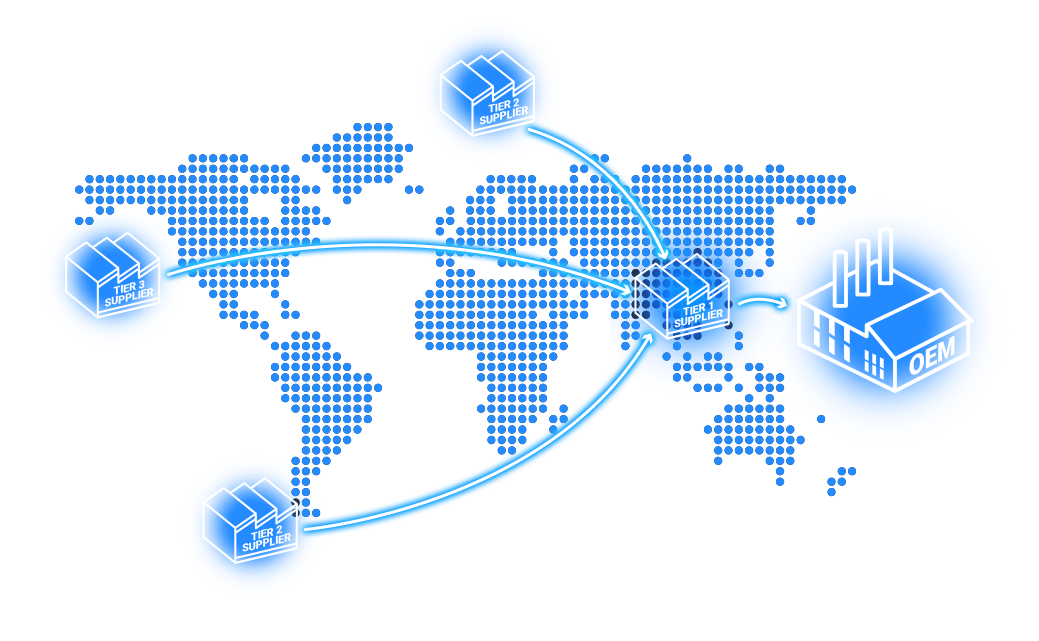

Supply chain monitoring

Don't let your supply chain suffer because of a lack of data visibility. Our cloud-based data management system connects OEMs to their supply base to provide visibility into production efficiency and quality of parts as they move through the supply chain.

See how PICO error-proofs the shop floor

We use our own software every day to stress test its capabilities. Hear how we use Pico MES to build Pico Hubs.

FAQs: Shop floor software for discrete manufacturing

What is PICO and how quickly can it be deployed in my factory?

PICO is a modular Manufacturing Execution System (MES) designed to help discrete manufacturers digitize and error-proof their assembly manufacturing operations. It is engineered for rapid deployment, allowing engineers to digitize processes and connect IoT tools in just a few hours.

What key features does PICO offer for error-proofing and operational visibility?

PICO error-proofs assembly manufacturing through digital work instructions and smart tool integrations. As operators build, tool data is automatically captured and analyzed in PICO to alert of errors, reducing scrap and rework.

How does PICO improve manufacturing accuracy and operator performance?

Manufacturers see improved product quality and process efficiency by employing PICO's interactive visual worker guidance on the shop floor, ensuring consistent builds regardless of who's on shift. Automated data capture replaces manual input, reducing human errors and enabling full backwards traceability for every part that moves through production.

Which business systems and tools can PICO integrate with?

PICO integrates with over 330+ commercially available assembly tools and devices such as fastening systems, pick-to-light systems, barcode scanners, and more. It also connects seamlessly to your Enterprise Resource Planning (ERP) system and other factory software systems.

Who benefits most from PICO, and what’s the expected return on investment?

PICO's software is suitable for small, mid-sized, and enterprise manufacturers with modular features that scale across production environments. It replaces risky, multi-year, costly deployments with a flexible, low-friction platform for an instantly measurable ROI.

Gain access to hundreds of solutions from a single platform

Bring your shop floor together — people, tools, and data all connected in one system. No rip and replace; just connections.