Process Efficiency

Identify trends and outliers to quickly adjust processes and improve throughput.

Make continuous improvement easier than ever by leveraging advanced analytics, real-time monitoring, full backwards traceability, and factory software integrations in PICO.

You’re collecting production data across the shop floor but don’t know how to use it to determine if you’re winning or losing.

Factory data is centralized, analytics are automated, and all parts are traceable with a complete build history record. You spend less time digging for actionable data, and more time improving.

"Our customers trust the data we share because we can clearly show where defects started, how they spread, and how to prevent them in the future."

Manufacturers are impressed with how quick and easy it is to trace production data in PICO.

Find out how one battery manufacturer leveraged traceability at the core of their quality management system (QMS) to streamline customer audits and help get their ISO 9001 certification in just 6 months.

Angelo Menotti

Heady of Quality Engineering

Lithos Energy

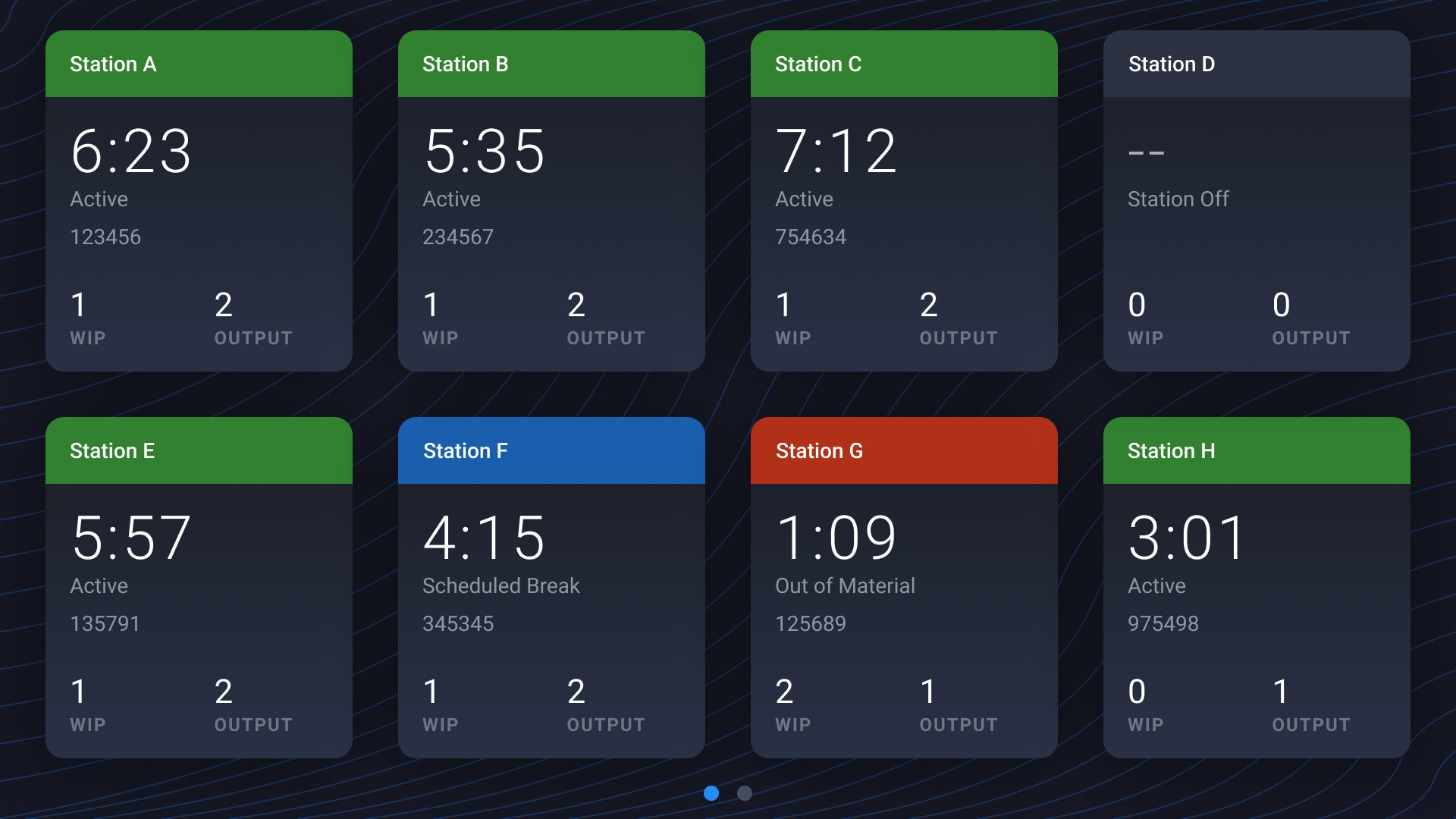

Process and workstation analytics are fully automated for easy tracking of cycle time, build time, output, and other key metrics. Analytics are updated in real-time as operators build.

Monitor shop floor activity in real-time through customizable dashboards. Respond to issues faster to reduce downtime and keep your operations running.

Every part built in PICO is contextualized to a process, operator, and workstation to provide a traceable “digital product passport”. Instantly find build data with a single search.

PICO integrates with ERP and other manufacturing software systems to create a robust factory tech stack. Enable instant data sharing for full transparency and get the most out of your production data.

#{ truncateText(item.metadescription) }

PICO empowers continuous improvement with real‑time analytics, advanced KPI dashboards, full backwards traceability, and seamless integration with ERP and other systems—helping you systematically enhance throughput, reduce rework, and drive lasting productivity gains.

PICO dashboards report on live cycle times, workstation outputs, and process efficiency—so teams can spot outliers, respond promptly to bottlenecks, and continuously optimize shop-floor performance.

Every part built in PICO is linked to its build context—including operator, workstation, and process—forming a “digital product passport.” You can instantly retrieve full build histories by searching part numbers, serial numbers, or job orders for audit readiness and root cause analysis.

PICO eliminates manual entry through automated data capture from integrated smart tools. This ensures clean, structured data across all builds and processes—forming the foundation for accurate real‑time analytics and ongoing process refinement.

PICO connects seamlessly with ERP and manufacturing systems to centralize data and share insights across your tech stack. This holistic transparency accelerates improvements, enabling smoother workflows and informed decision-making across departments.