No more digging through paper travelers. Gain instant access to every part's complete build history.

Eliminate paper records

Manual data entry is error-prone, burdensome, and inefficient.

No more digging through paper travelers. Gain instant access to every part's complete build history.

Manual data entry is error-prone, burdensome, and inefficient.

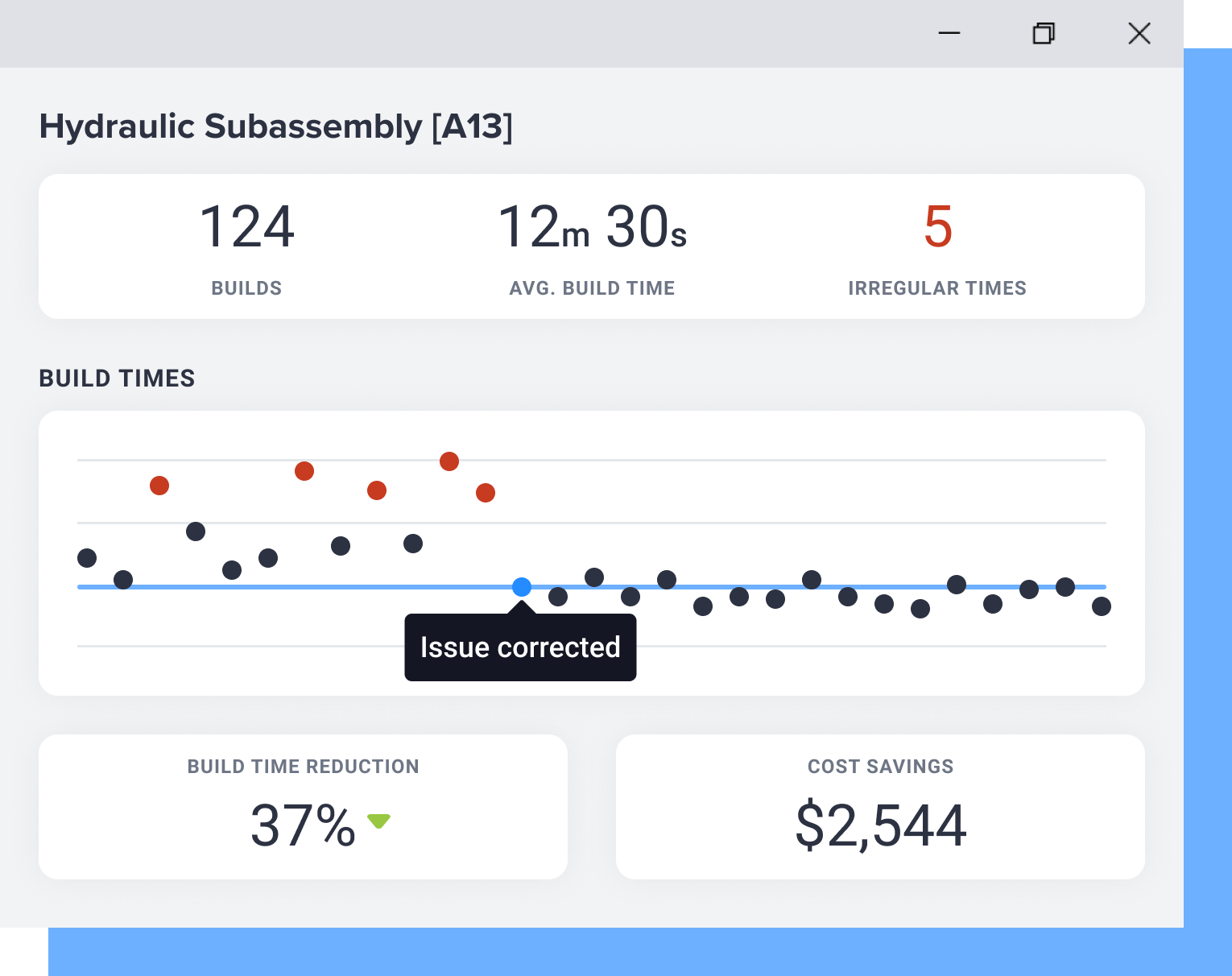

Easily identify defects, demonstrate how they happened, and present a resolution - all in one place.

Simply search by serial number, part number, or work order and see every associated part, process, and complete build history. PICO captures metadata and build data automatically and provides comprehensive build data tables for every part.

It's free to get started, or upgrade to the Essential plan to connect a barcode scanner for even faster parts tracking.

Enable traceability at your factory by:

Take a self-guided tour to see how easy & fast it is to find all of your build data in PICO.

"Our customers trust the data we share because we can clearly show where defects started, how they spread, and how to prevent them in the future."

Manufacturers are impressed with how quick and easy it is to track and trace production data in PICO.

Find out how one battery manufacturer uses PICO for all manufacturing traceability as part of their quality management system (QMS) to streamline customer audits and help get their ISO 9001 certification in just 6 months.

Angelo Menotti

Head of Quality

Lithos Energy

PICO's traceability feature is accessible to factories of all sizes and doesn't require advanced tools and technology to implement. Download our free Traceability Implementation Checklist and watch the on-demand webinar with Steve Tebbetts, Consultant at STEAM Services, to learn the easiest way to ditch paper records and start digitally tracing your factory data.

#{ truncateText(item.metadescription) }

Traceability is the ability to track materials, components, and production steps throughout the entire manufacturing process.

It allows manufacturers to isolate defects, conduct root cause analysis, comply with industry regulations, and reduce the scope of recalls.

PICO captures operator inputs, tool data, part scans, and process validation in real-time and ties them to serial numbers or work orders.

No. Pico MES can provide full traceability independently or alongside your ERP through integration.

Manual confirmations, inspection results, tool usage, timestamps, part numbers, and images are all captured and automatically stored.

Bring your shop floor together — people, tools, and data all connected in one system. No rip and replace; just connections.