Want to digitize fast without a full MES implementation? Use PICO to connect people, tools, and machines for instant error-proofing.

4,500

3,000

Start Here: See How PICO Error-Proofs Manual Assemblies

A Modular MES That's Built for Companies of All Sizes and Needs

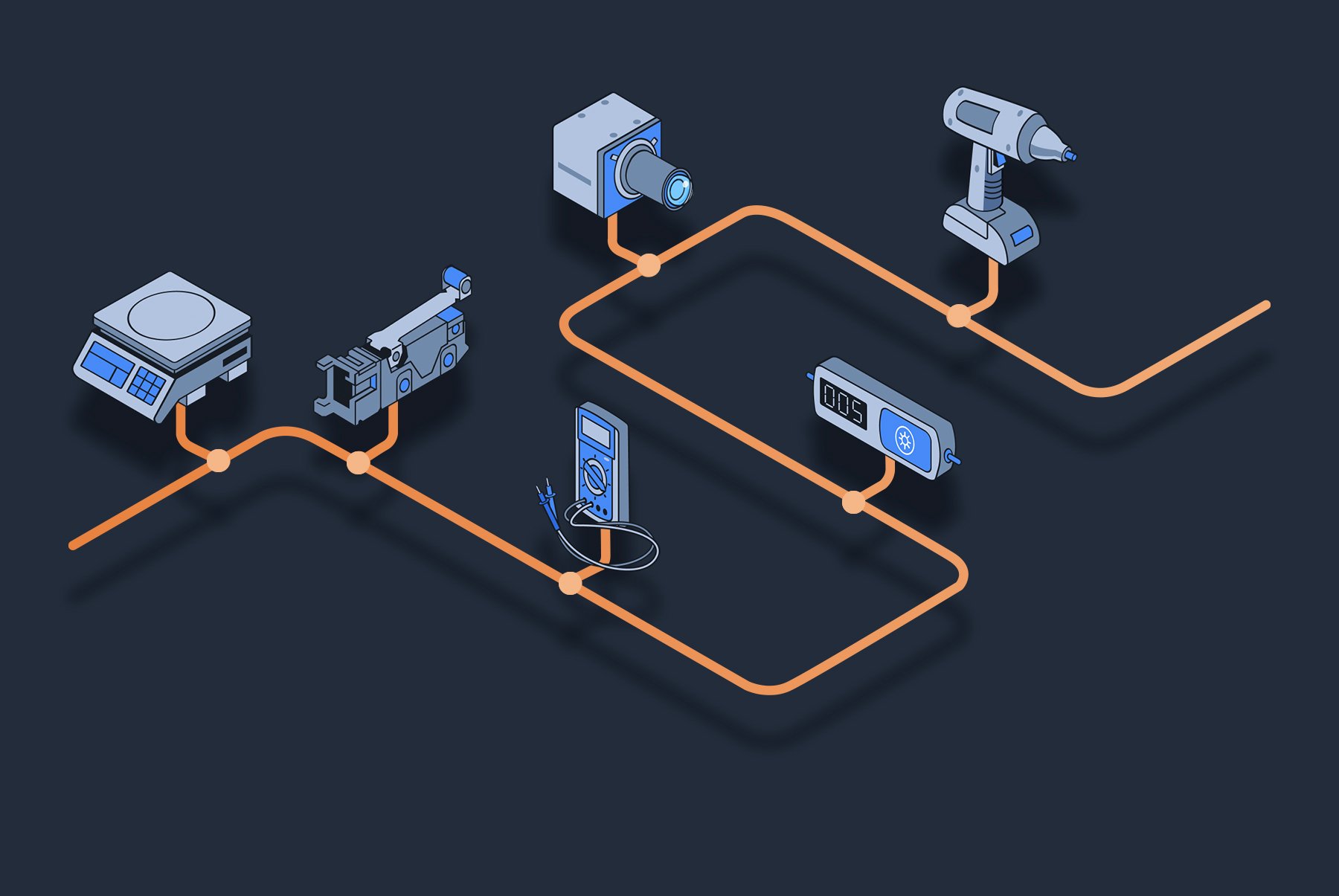

Unify data collection from every tool

On a shop floor that uses hundreds of different tools, isolating data by tool brand or workstation causes blind spots. PICO connects to your barcode scanners, torque tools, PLCs, and vision systems—no matter the brand. Feed tool data directly into your digital work instructions and build an audit trail in real time. Device integrations are 100% free for PICO customers.

Enforce standard work with visual operator guidance

In high-mix, low-volume environments with a lot of product variation, consistency can be difficult to maintain without standard work. Whether you're assembling industrial equipment or complex electronics, PICO's digital work instructions provide step-by-step operator guidance with layered content, colorful images, and built-in error-proofing so every build meets the same quality standard, regardless of who’s on shift.

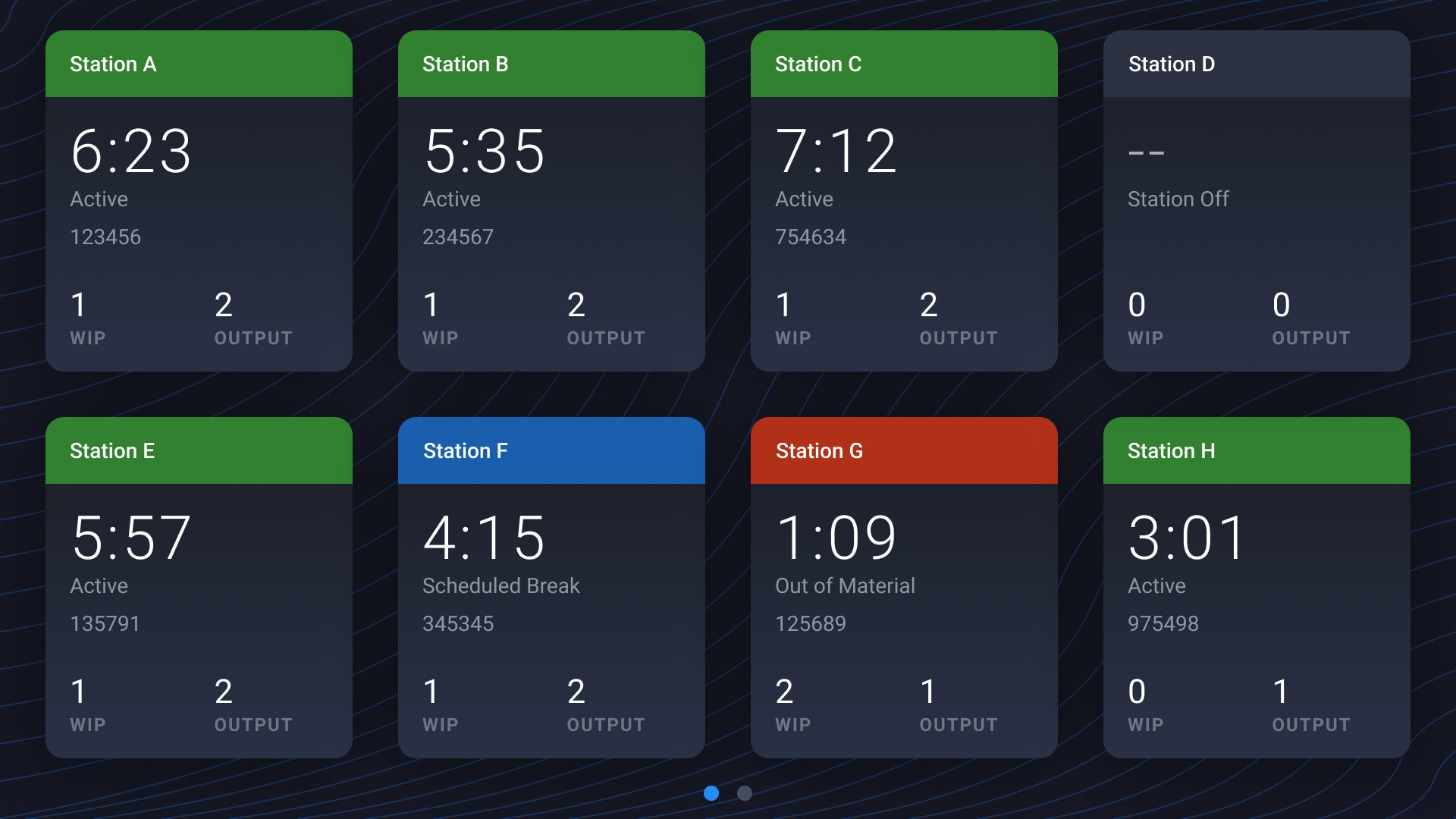

Gain real-time visibility on the shop floor

- "Am I winning or losing today?"

- "Are my operators consistently hitting their production targets?

- "Can I isolate my errors to who built the product and why?"

Arm the operations team with quick insights into throughput, yield, and operator performance. Enable them to respond to issues as they happen.

Integrate with ERP, PLM, QMS, and Other Business Systems

PICO was built to fit into your tech stack—not replace it. Whether you're running NetSuite, Odoo, or using SCADA platforms like Ignition, PICO connects easily to sync data between the shop floor and business systems. Connecting with existing technology infrastructure is where our customers realize the most ROI.

Trusted by manufacturers of all sizes

See how we support small manufacturers, mid-sized manufacturers, and enterprise teams with modular features designed for flexibility and fast adoption.

Intuitive and easy to use

Liam S.

Excellent integration capabilities and customer support

Martin G.

Easy set-up, helpful training tools

Paul C.

Compatible and easy to deploy

Elliot H.

A truly amazing team

Ted T.

Easy set up and maintenance

George F.

Ease of set-up and deployment

Matt B.

Simple user interface

Caleb M.

Speedy deployment & easy to create work instructions

Demi C.

Smooth integration & fantastic customer service

Michael H.

Saves $$ on repairs and re-works

Joe E.

Effective user interface and smart tools integration

Gabe A.

Fast, efficient onboarding

Jeremy R.

Amazing capabilities for a small price

Raakesh B.

Flexibility and Support

Talen G.

Dramatic Production Floor Improvement

Greg W.

Good MES, very helpful

Donald W.

Pico is a must have!

Chris S.

Simple and Easy to use MES

Trevor O.

PICO MES

Jarrett H.

Heavy Duty Truck Manufacturer

Cody C.

Repeatability and consistency

Ben M.

Great entry point

Glenn H.

Real stories. Real results.

Read more on

#{ item.name }

#{ truncateText(item.metadescription) }

No posts available

Gain access to hundreds of solutions from a single platform

Bring your shop floor together — people, tools, and data all connected in one system. No rip and replace; just connections.