#{ item.name }

#{ truncateText(item.metadescription) }

Many modern factories are operating hybrid manufacturing environments consisting of both manual and automated workflows. Yet even in complex environments, these workflows often operate in silos. Machine data lives in one system, manual data in another, and integrating them often requires custom engineering or complex middleware that may be out of reach for small or mid-sized manufacturers. The result is slow access to information, incomplete traceability, and fragmented visibility that makes day-to-day operations more difficult than they should be.

PICO solves this by providing a unified, no-code approach to machine and equipment integration. Our platform brings automated equipment and manual tasks together so manufacturers can run truly connected hybrid environments with real-time data, error-proofed workflows, and full production traceability. Through PICO's edge devices and industrial protocols like OPC-UA and Modbus, manufacturers can integrate automated equipment and systems just as easily as manual assembly tools. This article explores how it works and what's included in PICO's machine integration capability.

Although we're living in the age of AI and automation, even the most modern factories still depend on some human-led tasks: verification, inspection, loading, setup, material prep, and more. However, when those manual steps are not connected to machine activities, teams suffer from isolated data, delayed insights, and limited understanding of how operator actions influence automated processes. Without unifying human and machine activities, production teams struggle to correlate outcomes, maintain consistent process control, and achieve end-to-end part traceability.

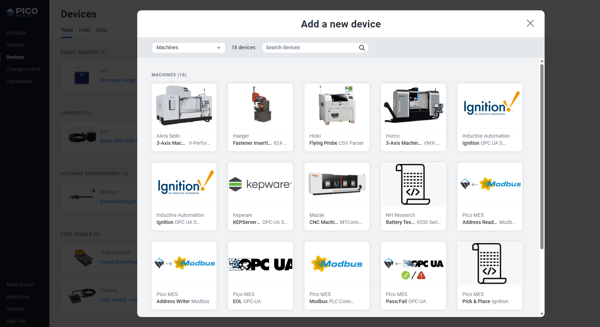

PICO treats machine integrations the same way it treats tool integrations: simple, intuitive, and entirely no-code. All automated equipment connections are configured within the Device Library, right alongside your manual assembly tools, dramatically reducing setup time and eliminating the need for custom PLC programming or middleware. Equipment integrations rely on direct connections to the PICO Hub edge device, shared networks, or industry standard communication protocols such as OPC-UA or Modbus.

By centralizing manual and automated workflows in one system, PICO becomes the operational layer that ties together machinery, operators, and production data—filling a critical gap left by traditional MES systems and enabling a modern, connected manufacturing environment.

👉 PICO doesn't replace HMI/SCADA systems that specialize in machine automation—we complement them. Learn more about integrating SCADA systems with PICO.

Once connected, these machines become part of the same guided workflows operators already use for manual tasks. PICO enables:

All of these actions are done without coding or integrating external software. More importantly, every action—manual or automated—is recorded and tied to the part being produced, enabling full backwards traceability across the shop floor.

Here are some examples of the types of machines PICO integrates with:

Type |

Integration |

Brands |

|---|---|---|

| CNC Machines |

Machine state monitoring, cycle time tracking, tool change analysis, error state alerting |

|

| Hydraulic Fastener Insertion System |

Fastening cycle tracking |

Haeger |

| Flying Probe Machine |

Determine pass/fail result, capture cycle time |

|

| End-of-Line (EOL) Tester |

Run tests, validate assemblies through PLC, HiPot, or peripheral sensors |

|

| Laser Engraver |

Control start/stop of etching process |

|

| PLC |

Read/write machine data, collect test results & measurements, track EOL checks |

OPC-UA, Modbus |

➡️ Watch this demo video to see how PICO integrated with a FANUC Cobot via Modbus:

By consolidating manual and machine data into a single platform, PICO delivers real-time visibility across every operator action, machine cycle, and measurement point. Manufacturers gain more consistent process control, eliminate errors caused by system fragmentation, and improve quality by ensuring every workflow—human or machine—follows the correct sequence without exception.

This unified environment also enables full part traceability across hybrid operations and unlocks deeper insights into production performance. Operators benefit from a single, guided interface rather than navigating separate machine screens or systems, while engineers and leaders gain the clarity needed to optimize processes with confidence. The result is a more connected, efficient, and scalable operation—one where machine integration, equipment integration, and the MES work together to support continuous improvement.

#{ truncateText(item.metadescription) }

Bring your shop floor together — people, tools, and data all connected in one system. No rip and replace; just connections.